Steve Sanford

Well-known member

All~

In response to Joe Daly's inquiry, I have expanded the post on my own website to include 52 images of the conversion process. So here is a lighter presentation. For the complete blow-by-blow, go to "How I Do It" tab:

http://stevenjaysanford.com/sunfish-to-gunning-boat/

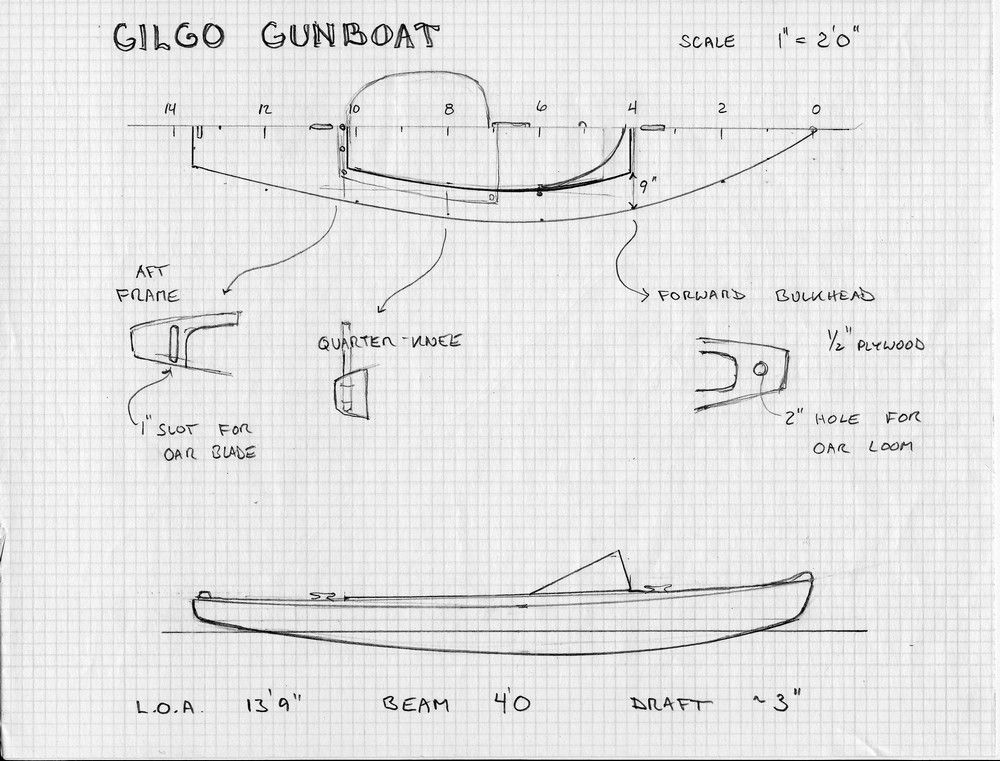

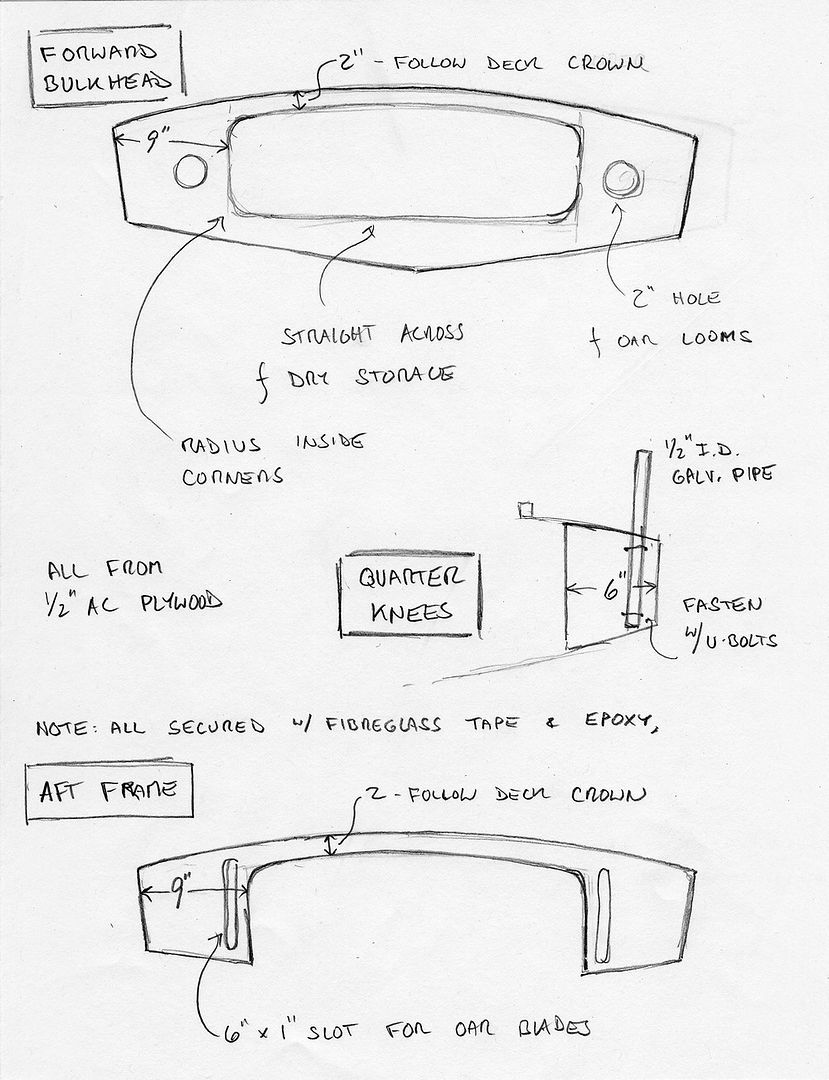

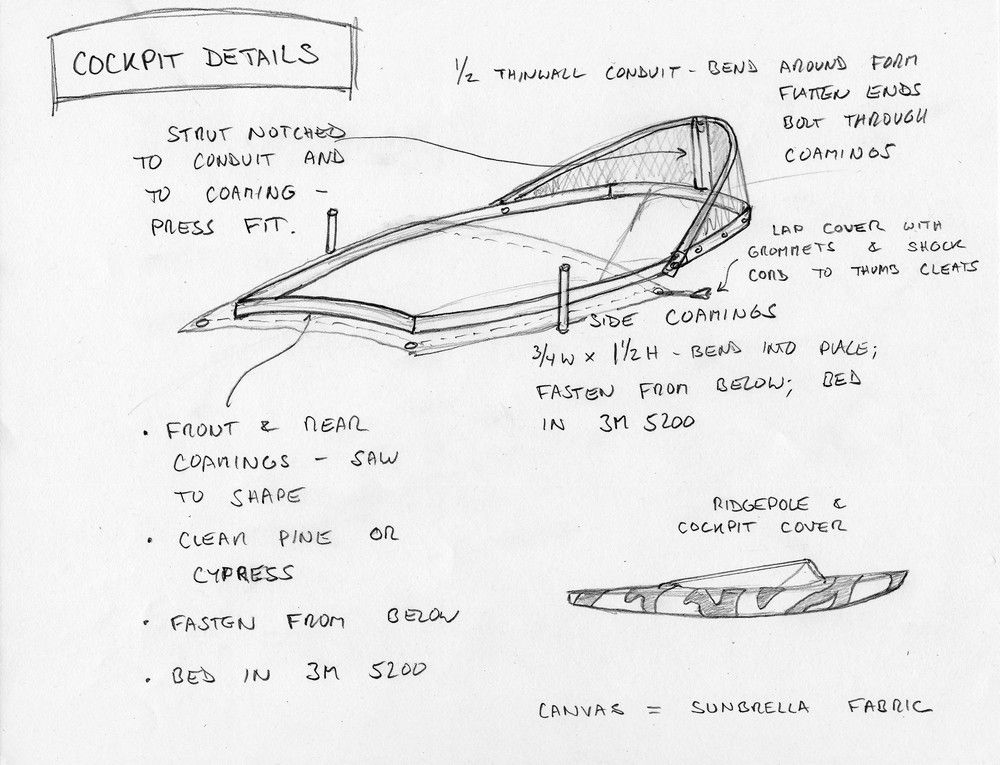

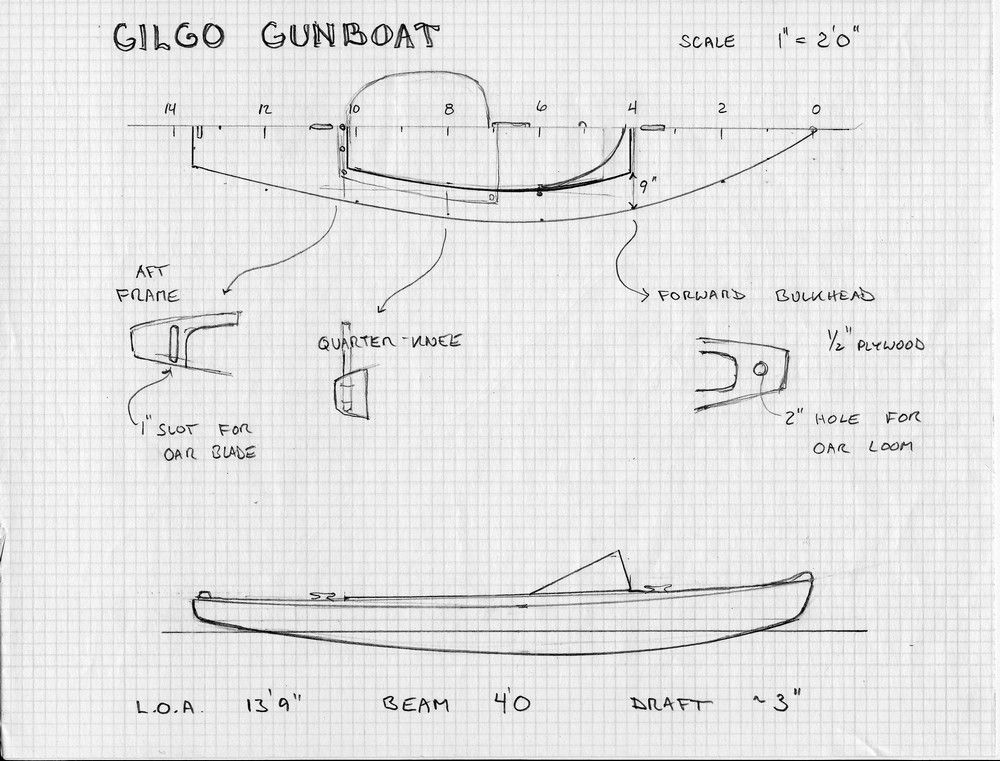

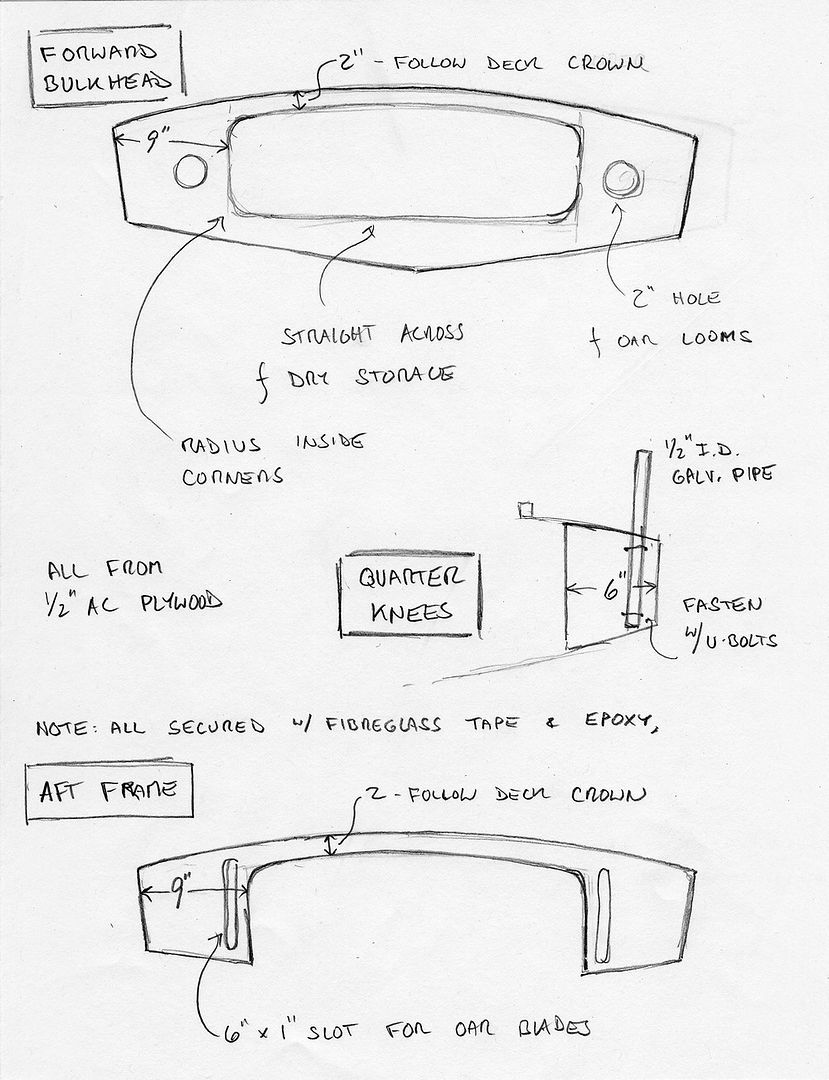

Here are the sketches I started with. Exact dimensions and construction details commonly change as I get to work.

I squared up my markings by using the transom as my baseline.

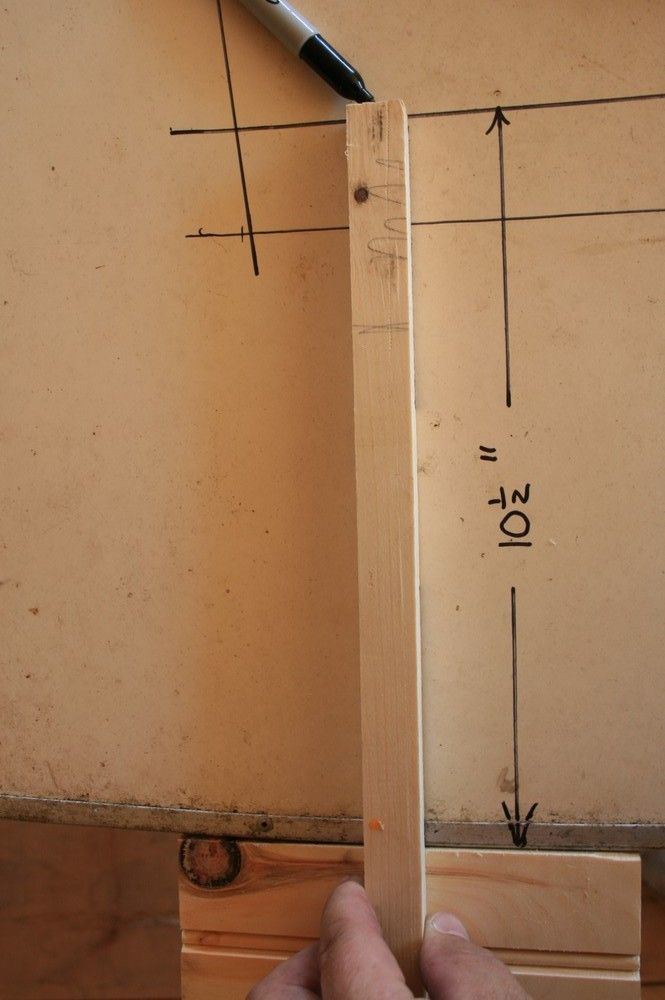

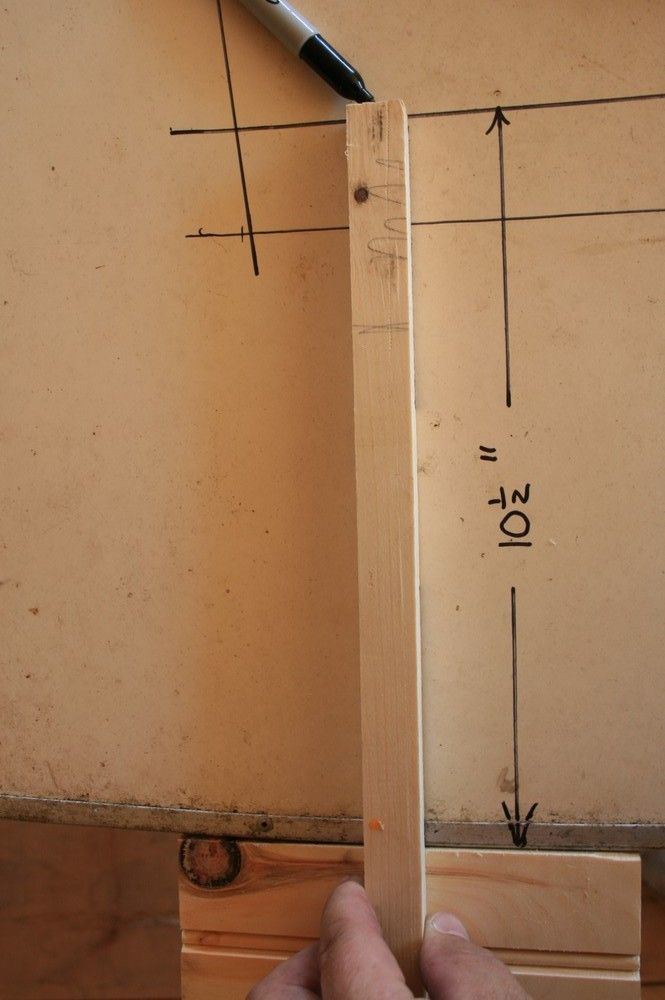

My side decks wound up at 10.5 inches - and I made this jig to follow the curve of the gunwales.

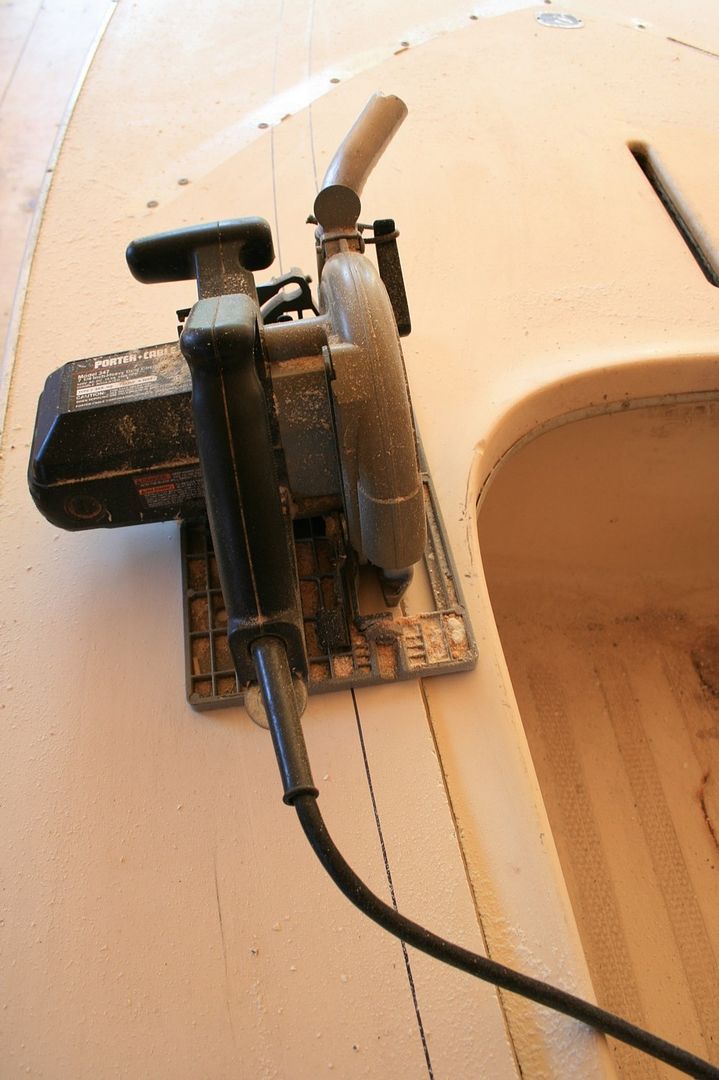

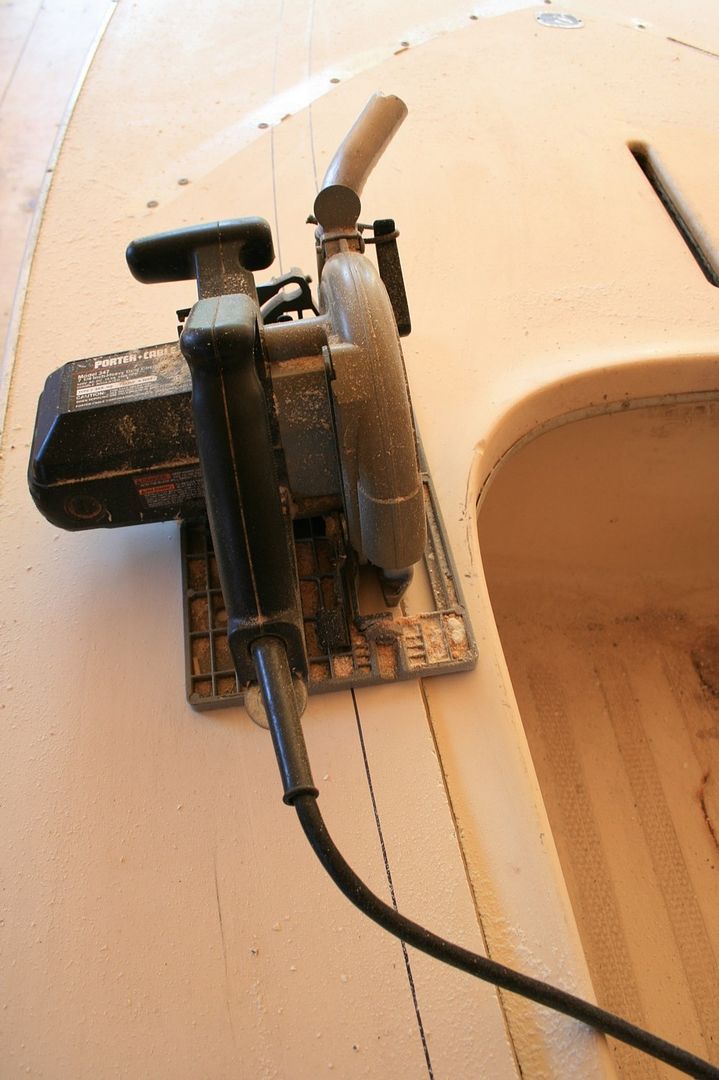

I used my skilsaw to do most of the cutting.

Then I removed all of the soggy foam floatation and the extraneous pieces of "framing".

I leveled up the hull in the shop with chocks screwed into the horses.

I used some clear treated SYP for the purlins - and ran them about 8 or 10 inches longer than the cockpit ends to avoid creating hard spots in the deck. They are fastened with 3M 5200 and SS panhead screws. The keel has been filled with insulation spray foam and will get covered with 'glass later on.

The fore and aft bulkheads are 1/2-inch AC plywood. They are 'glassed in along sides and bottom - but set in 5200 along their top edges.

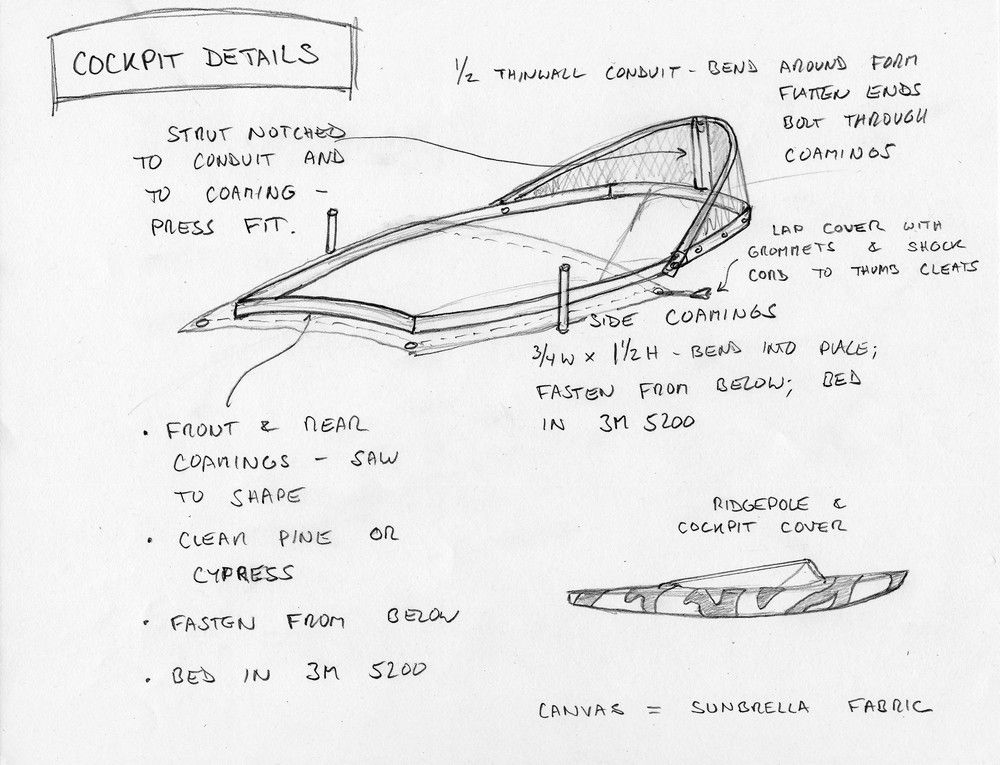

Coamings are screwed into purlins and bulkheads - set in 5200, of course.

Backrest doubles as rowing seat - about 4 inches up off the floorboards.

It is held in place by a permanent chock on the floorboard.

The strut that holds the dodger/cowling up is tied to the bulkhead so it cannot be lost. The oars stow as planned in the bulkheads.

Lap cover is held at its foot by Common Sense fasteners - and at its upper end by shock cord over thumb cleats - so it "gives" when you sit up to shoot.

Oarlock stanchions are secured with galvanized carriage bolts - through backers made of half-inch ply and a bevel piece so that the washers and nuts land on a square surface.

Wooden (SYP) fairlead keeps the stern anchor line in place.

Here's the Gilgo Gunboat ready-to-hunt - on the Hemlock Swamp right here at Pencil Brook Farm.

And on the salt waters of Great South Bay.

All the best,

SJS

In response to Joe Daly's inquiry, I have expanded the post on my own website to include 52 images of the conversion process. So here is a lighter presentation. For the complete blow-by-blow, go to "How I Do It" tab:

http://stevenjaysanford.com/sunfish-to-gunning-boat/

Here are the sketches I started with. Exact dimensions and construction details commonly change as I get to work.

I squared up my markings by using the transom as my baseline.

My side decks wound up at 10.5 inches - and I made this jig to follow the curve of the gunwales.

I used my skilsaw to do most of the cutting.

Then I removed all of the soggy foam floatation and the extraneous pieces of "framing".

I leveled up the hull in the shop with chocks screwed into the horses.

I used some clear treated SYP for the purlins - and ran them about 8 or 10 inches longer than the cockpit ends to avoid creating hard spots in the deck. They are fastened with 3M 5200 and SS panhead screws. The keel has been filled with insulation spray foam and will get covered with 'glass later on.

The fore and aft bulkheads are 1/2-inch AC plywood. They are 'glassed in along sides and bottom - but set in 5200 along their top edges.

Coamings are screwed into purlins and bulkheads - set in 5200, of course.

Backrest doubles as rowing seat - about 4 inches up off the floorboards.

It is held in place by a permanent chock on the floorboard.

The strut that holds the dodger/cowling up is tied to the bulkhead so it cannot be lost. The oars stow as planned in the bulkheads.

Lap cover is held at its foot by Common Sense fasteners - and at its upper end by shock cord over thumb cleats - so it "gives" when you sit up to shoot.

Oarlock stanchions are secured with galvanized carriage bolts - through backers made of half-inch ply and a bevel piece so that the washers and nuts land on a square surface.

Wooden (SYP) fairlead keeps the stern anchor line in place.

Here's the Gilgo Gunboat ready-to-hunt - on the Hemlock Swamp right here at Pencil Brook Farm.

And on the salt waters of Great South Bay.

All the best,

SJS