stephen thompson

New member

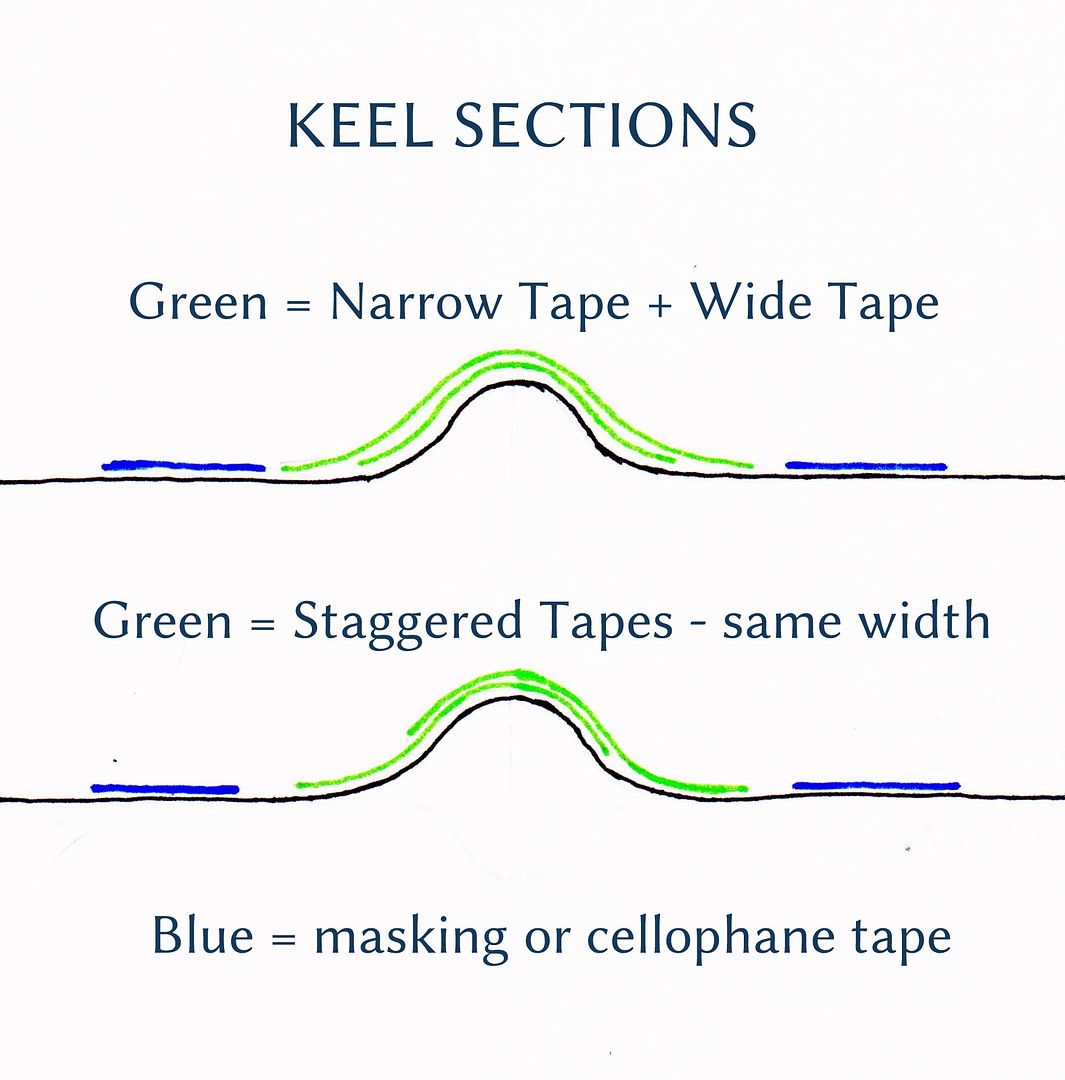

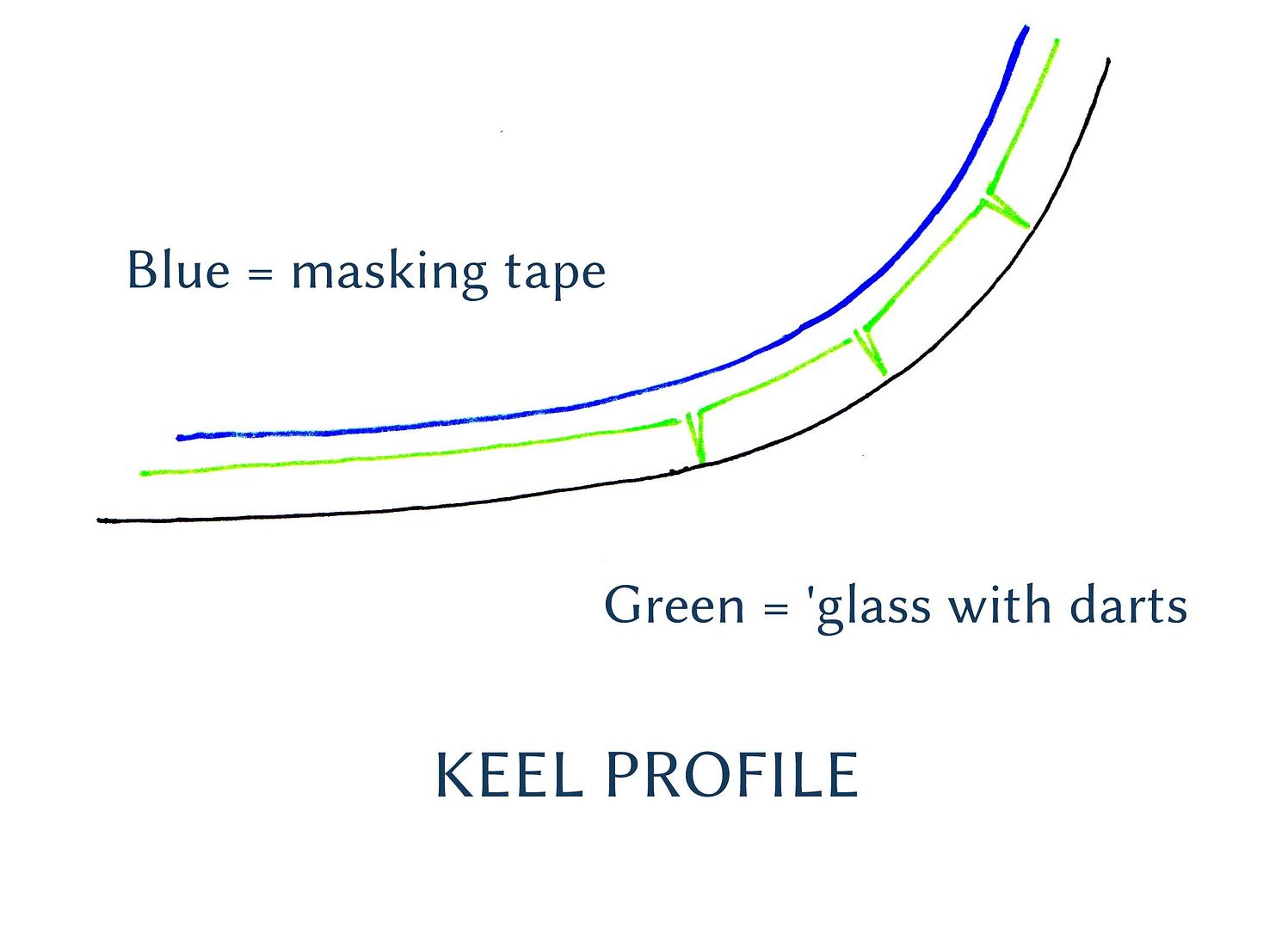

What's the best way to lay 4 inch wide glass over the angle of the keel.Should I do it in two pieces and overlap them in the center of the keel or use small pieces over lapping them as I go down the keel or use one big piece and make little slits on each side and overlap them as I go over the curvature/angle of the keel.

Thanks, Steve

Thanks, Steve