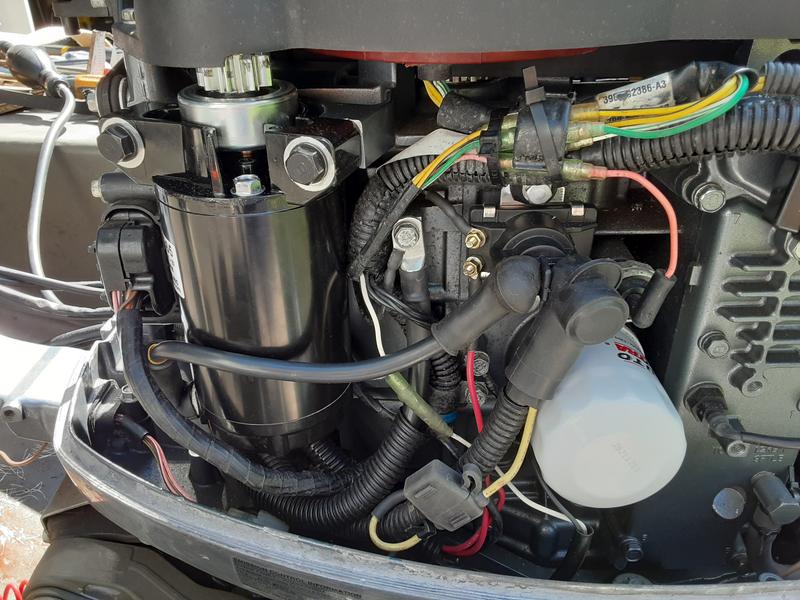

I'm in the process of changing my flywheel on my Yamaha F40 for a toothed flywheel so I can add electric start. I pulled the flywheel and the woodruff key on the crankshaft is sheared (and the flywheel rotated a bit, but not much, obviously not too much as the motor was running well). The keys are out of stock and are backordered everywhere and expected Sept 30 at Yamaha USA.

I checked with all the big places I know of Boats.net, Crowley and Sim along with every other place I could find that listed the part number. Other superstores out there or places to look?

Were it a regular piece of equipment I'd just measure and get a new one from anywhere, what are people's thought on that? It had sheared once, so id want the best part possible. It is in 2 pieces so tougher to get a good measurement if I went that route.

Thoughts?!?!?

I checked with all the big places I know of Boats.net, Crowley and Sim along with every other place I could find that listed the part number. Other superstores out there or places to look?

Were it a regular piece of equipment I'd just measure and get a new one from anywhere, what are people's thought on that? It had sheared once, so id want the best part possible. It is in 2 pieces so tougher to get a good measurement if I went that route.

Thoughts?!?!?

Last edited: