PART 1. Discovery

Going back six years ago I was cruising the local estate sale listings and ran across a picture (below) that jumped out at me. "What a cool vise" I thought to myself even though I could only see a portion of it. So off to the estate sale I went dragging a coworker with me to help load should it still be there. It was, and not only was there one vise, but there were two! For a fee the vises were mine and the sad bastard bench they were stuck to.

Back at the workshop I started looking the bench over and realized I had sold it way short. There was a lot of character there despite it being horribly abused. Evidently the bench was left standing in water as the legs rotted from the ground up. Trying to save the bench a previous owner whacked all four legs off just below the doors and nailed 2x4s to the stumps to keep it together. A quadruple amputee was now in my care. I could save it, but it would have to wait.

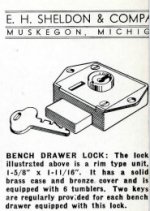

Looking the bench over I found a decal identifying the original maker, E.H. Sheldon and Co. from Muskegon, Michigan. Along with it were several union labels that narrow down when the bench was built and give more clues.

Armed with this info I started googling and uncovered the fact that E.H. Sheldon manufactured workbenches, vises, and even lathes and other woodworking machinery since the late 1800s and was best known for equipping trade schools and shop classes.

More info on the company history can can be found at the link below.

http://www.vintagemachinery.org/...x/detail.aspx?id=740

The vises are somewhat of a mystery. There are no markings on them and nowhere in any Sheldon publication have I been able to find any information about them. They are however very much the original vises. No questioning that fact.

Below is the quick release vise popularized by Christopher Schwarz that Sheldon is known for and very well documented in Sheldon's literature. Sheldon made other vises too but nothing like the ones on my workbench. So I did some digging...

After many searches I ran across a vise, W.C. Toles rapid acting #20, that was popular and common during the early part of the last century and IDENTICAL except for two things. The vises on my bench are not rapid acting, meaning there is no quick release, and they do not have the Toles markings. Other than that they are identical to the #20 in every possible way. My theory is Sheldon either made a copy, or they bought unmarked vises from Toles. I suspect its the latter. I mean why would you put a competitor's name on your product?

Another item on the workbench that intrigued me were the bench dogs. The bench doesn't have a series of holes to insert your traditional dog into. Rather it has two metal "pop-up" dogs conveniently located. A little literature review revealed this was a patented design by E.H. Sheldon. Until yesterday I could find no information on these round dogs. Every illustration by Sheldon, including the original patent drawings, showed the dogs having a square base. Then I got lucky and uncovered a 1940 catalog that shows the round base dogs. My hunch is the round shape was easier to inset in the bench top so Sheldon dropped the squared shape in favor of round.

Time to start the teardown and restoration...

Going back six years ago I was cruising the local estate sale listings and ran across a picture (below) that jumped out at me. "What a cool vise" I thought to myself even though I could only see a portion of it. So off to the estate sale I went dragging a coworker with me to help load should it still be there. It was, and not only was there one vise, but there were two! For a fee the vises were mine and the sad bastard bench they were stuck to.

Back at the workshop I started looking the bench over and realized I had sold it way short. There was a lot of character there despite it being horribly abused. Evidently the bench was left standing in water as the legs rotted from the ground up. Trying to save the bench a previous owner whacked all four legs off just below the doors and nailed 2x4s to the stumps to keep it together. A quadruple amputee was now in my care. I could save it, but it would have to wait.

Looking the bench over I found a decal identifying the original maker, E.H. Sheldon and Co. from Muskegon, Michigan. Along with it were several union labels that narrow down when the bench was built and give more clues.

Armed with this info I started googling and uncovered the fact that E.H. Sheldon manufactured workbenches, vises, and even lathes and other woodworking machinery since the late 1800s and was best known for equipping trade schools and shop classes.

More info on the company history can can be found at the link below.

http://www.vintagemachinery.org/...x/detail.aspx?id=740

The vises are somewhat of a mystery. There are no markings on them and nowhere in any Sheldon publication have I been able to find any information about them. They are however very much the original vises. No questioning that fact.

Below is the quick release vise popularized by Christopher Schwarz that Sheldon is known for and very well documented in Sheldon's literature. Sheldon made other vises too but nothing like the ones on my workbench. So I did some digging...

After many searches I ran across a vise, W.C. Toles rapid acting #20, that was popular and common during the early part of the last century and IDENTICAL except for two things. The vises on my bench are not rapid acting, meaning there is no quick release, and they do not have the Toles markings. Other than that they are identical to the #20 in every possible way. My theory is Sheldon either made a copy, or they bought unmarked vises from Toles. I suspect its the latter. I mean why would you put a competitor's name on your product?

Another item on the workbench that intrigued me were the bench dogs. The bench doesn't have a series of holes to insert your traditional dog into. Rather it has two metal "pop-up" dogs conveniently located. A little literature review revealed this was a patented design by E.H. Sheldon. Until yesterday I could find no information on these round dogs. Every illustration by Sheldon, including the original patent drawings, showed the dogs having a square base. Then I got lucky and uncovered a 1940 catalog that shows the round base dogs. My hunch is the round shape was easier to inset in the bench top so Sheldon dropped the squared shape in favor of round.

Time to start the teardown and restoration...

Last edited: