I have the boat in hand now, and picked up a new 6 hp Suzuki to drive it. Paint on the way from Lou at LS+B. Took her out for a test run last Friday, and the 6 (1) all I want to carry and (2) good for just under 10 knots at half throttle break in speed. I'm guessing I won't get much more by pushing it harder, and glad I did not get an 8 or 9.9 with the extra weight.

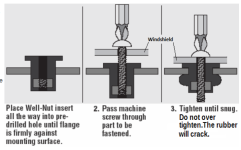

One of my intended uses for this boat is river fishing, and with shad season just around the corner, I'd like to mount a roller on the bow for an anchor. I have the hardware from a canoe, but am wondering about how to mount on aluminum. This is more difficult on the GSB than it otherwise might be, because about 3' of the bow is filled with floation inside and covered with a rounded deck. There is also a metal tab with a bow eye mounted dead center at the bow. Do I need to take bow apart and pull out the floation, then bolt the bow roller through the aluminum to a piece of scrap wood and then refill the bow with floatation foam? Any ideas on how to get a safe mount without taking the bow apart? I'll try to grab some photos this weekend when I have time.

One of my intended uses for this boat is river fishing, and with shad season just around the corner, I'd like to mount a roller on the bow for an anchor. I have the hardware from a canoe, but am wondering about how to mount on aluminum. This is more difficult on the GSB than it otherwise might be, because about 3' of the bow is filled with floation inside and covered with a rounded deck. There is also a metal tab with a bow eye mounted dead center at the bow. Do I need to take bow apart and pull out the floation, then bolt the bow roller through the aluminum to a piece of scrap wood and then refill the bow with floatation foam? Any ideas on how to get a safe mount without taking the bow apart? I'll try to grab some photos this weekend when I have time.