You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

shell lake mallard queen I.D.

- Thread starter bob welsh

- Start date

Steve Sanford

Well-known member

Bob~

Did that old Chase & Sanborn can come with the boat?

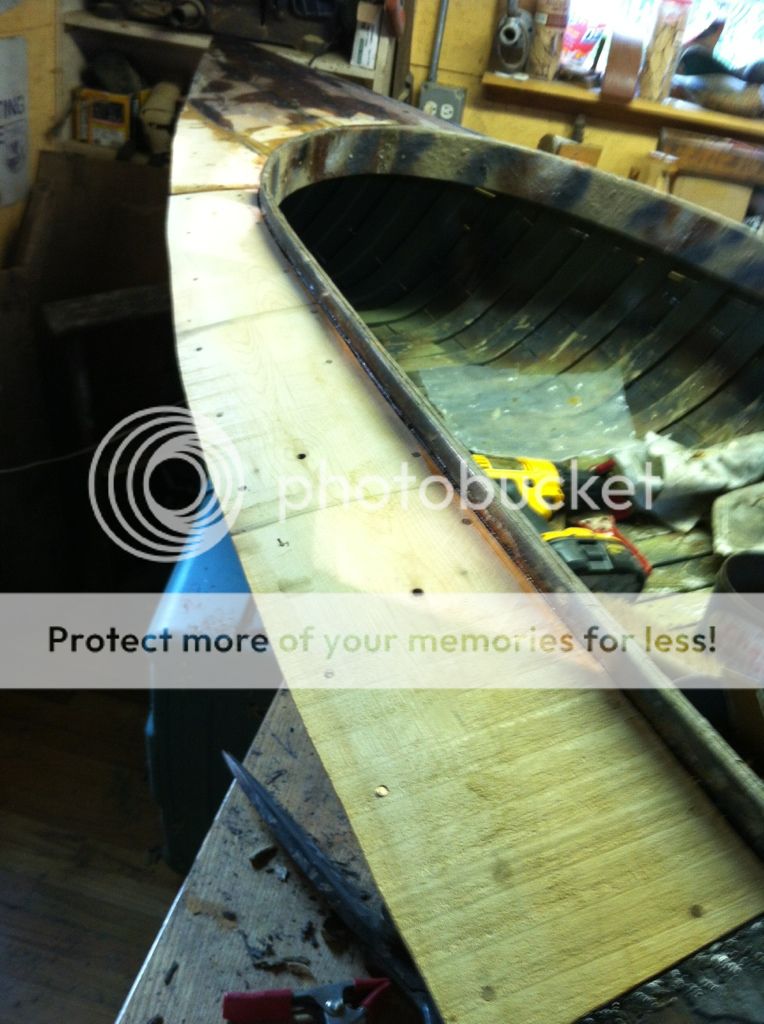

Great work on the decks.

SJS

Did that old Chase & Sanborn can come with the boat?

Great work on the decks.

SJS

Bob,

I hope you are going to canvas the outside of this boat, after all the great woodwork you did restoring it? The shape of this boat would be a lot easier to canvas, than a canoe would be.

Check the archives for Craig Carters posts on his Shell Lake Mallard Queen, he bought from me. He sent his boat to a place in Maine, I believe, to have it completely restored.

The filling of the canvas and proper care of the craft after restoration is crucial for a long life. Make sure the boat hull is completely in the water before you get in. I've seen guys with nice cedar strip canoes have half of the craft up on shore and step in and push the rest of it in with the paddle. "That's what the fiberglass strip on the end of the paddle is for", is their response.

Great job on a fine old boat!!

Art

I hope you are going to canvas the outside of this boat, after all the great woodwork you did restoring it? The shape of this boat would be a lot easier to canvas, than a canoe would be.

Check the archives for Craig Carters posts on his Shell Lake Mallard Queen, he bought from me. He sent his boat to a place in Maine, I believe, to have it completely restored.

The filling of the canvas and proper care of the craft after restoration is crucial for a long life. Make sure the boat hull is completely in the water before you get in. I've seen guys with nice cedar strip canoes have half of the craft up on shore and step in and push the rest of it in with the paddle. "That's what the fiberglass strip on the end of the paddle is for", is their response.

Great job on a fine old boat!!

Art

bob welsh

Well-known member

Art, I know its a no no but its glass on this one. Im not intimidated by the canvas,just this one had a lot of problems that it made it a good candidate for glass. I have taken the measurments and if a new one is buily it will be canvas. I saw Craig Carters post and have contacted him. His boat was done by a pro and turned out fantastic. Thanks for your imput as I came across pics of your old boat . bob

Kip Jensen

Member

Ok bob ,what's your address? I'm coming over to help, or watch, or what ever. Just kidding, no really ,what's your address? ( just kidding)

bob welsh

Well-known member

Kip, nobody wants to come to Chicago . With all the shootings lately maybe Kevlar should be the covering of choice. Looking for a pic of an original seat that would have gone with the boat if anyone has one.Also on the subject of oar lock positions. It looks like the placement would allow the oarsman to use the seat in back or in the front of the locks depending on the load or if shooting with another hunter. I wonder if anyone can elaborate on this.

Lou Tisch

Well-known member

Kip, nobody wants to come to Chicago . With all the shootings lately maybe Kevlar should be the covering of choice. Looking for a pic of an original seat that would have gone with the boat if anyone has one.Also on the subject of oar lock positions. It looks like the placement would allow the oarsman to use the seat in back or in the front of the locks depending on the load or if shooting with another hunter. I wonder if anyone can elaborate on this.

Bob,

Actually, my wife & I'll be heading over to Chicago this weekend with some friends from Elkhart. We're going to a Cubs game at Wrigley Field. That's one of my buddy's "bucket list items" so we're making a weekend of it.

Here's a Mallard Queen seat if memory works at my age.

View attachment MallQueen-Seat-01.jpg

View attachment MallQueen-Seat-02.jpg

View attachment MallQueen-Seat-03.jpg

View attachment MallQueen-Seat-04.jpg

Steve Sanford

Well-known member

Bob~

You're flying along!

A couple of questions:

1) Do you let your first coat of resin cure to serve as a sealer ?

2) Did you have to fill the seams before applying resin? If so, what did you use?

3) Will you be putting a single layer of 'glass (6 oz? 10 oz?) on the hull with it doubled over the keel area?

All the best,

SJS

You're flying along!

A couple of questions:

1) Do you let your first coat of resin cure to serve as a sealer ?

2) Did you have to fill the seams before applying resin? If so, what did you use?

3) Will you be putting a single layer of 'glass (6 oz? 10 oz?) on the hull with it doubled over the keel area?

All the best,

SJS

bob welsh

Well-known member

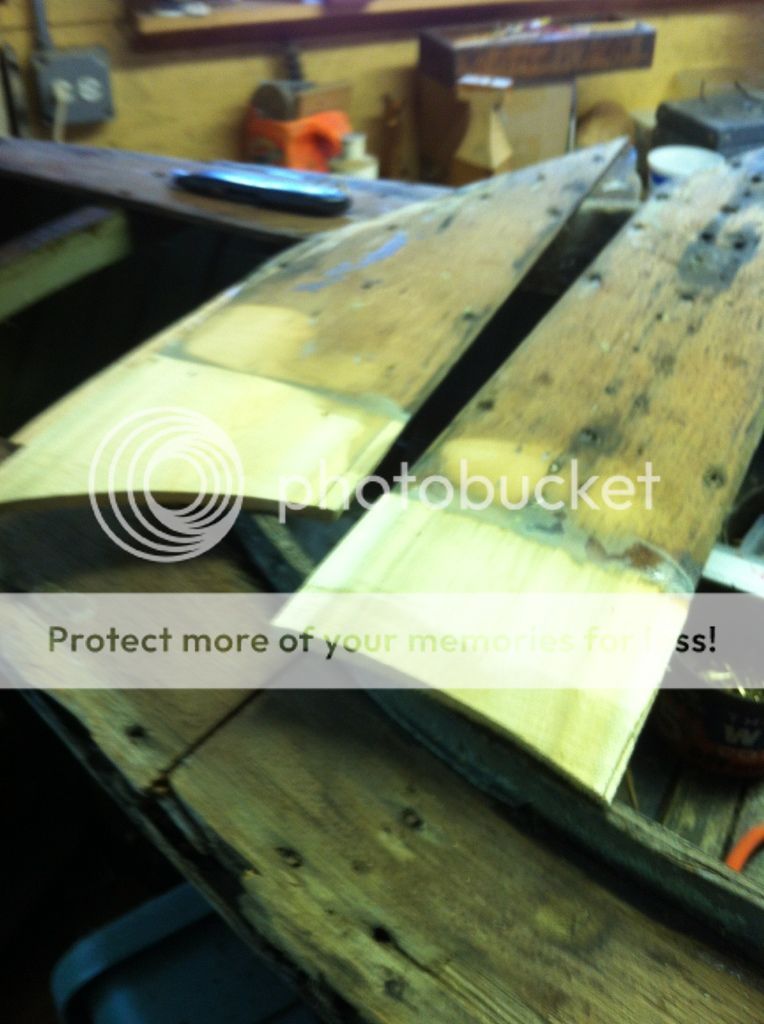

I tried Lou's method of using 3m windshield sealant on the big gaps,so far so good. I mixed up a batch of resin with cabosil added and squeeged it over the whole boat. This stuff was more resin than cabosil but still had body. While this was setting up I cut the 6 oz cloth to roughly the shape of the bottom and layed it in the already wet surface and applied just resin over that. I don't know if it's acceptable or not but it works for me. I can squeegee the resin on top of the cloth and smooth the thickens epoxy underneath at the same time

Steve Sanford

Well-known member

Bob~

Sounds like you've nailed it - with all the materials and layers curing together.

Thanks for the info abut Lou's 3M adhesive. Your thread and his are great tutorials.

All the best,

SJS

Sounds like you've nailed it - with all the materials and layers curing together.

Thanks for the info abut Lou's 3M adhesive. Your thread and his are great tutorials.

All the best,

SJS