You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's on your WORK BENCH - July 2020

- Thread starter Steve Sanford

- Start date

Pat Gregory

Well-known member

Awesome scaup Pete!

MLBob Furia

Well-known member

[size 4] Another spattered mallard hen

View attachment IMGP4757 (3) (993 x 660).jpg

View attachment IMGP4749 (2) (993 x 660).jpg

View attachment IMGP4755 (2) (941 x 620).jpg

View attachment IMGP4757 (3) (993 x 660).jpg

View attachment IMGP4749 (2) (993 x 660).jpg

View attachment IMGP4755 (2) (941 x 620).jpg

Jim Cricket

Member

Hi Folks,

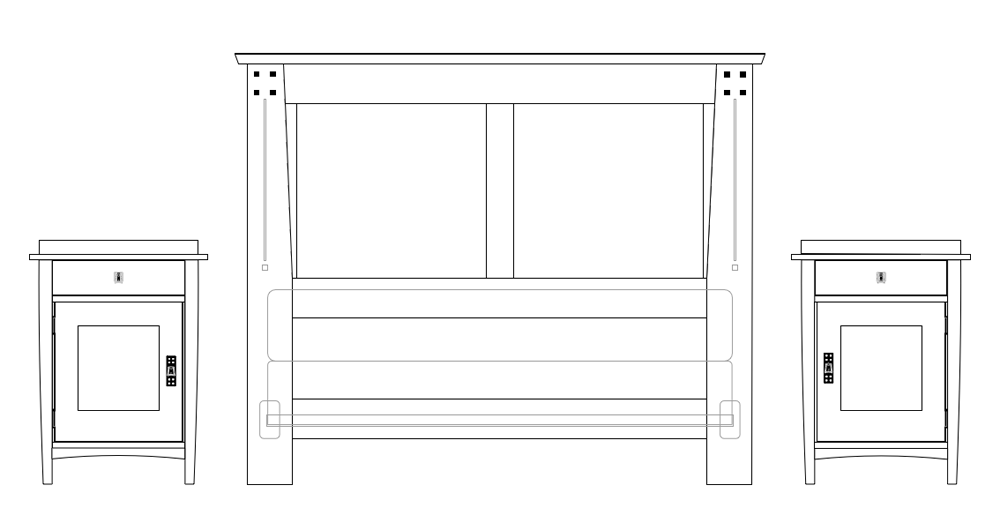

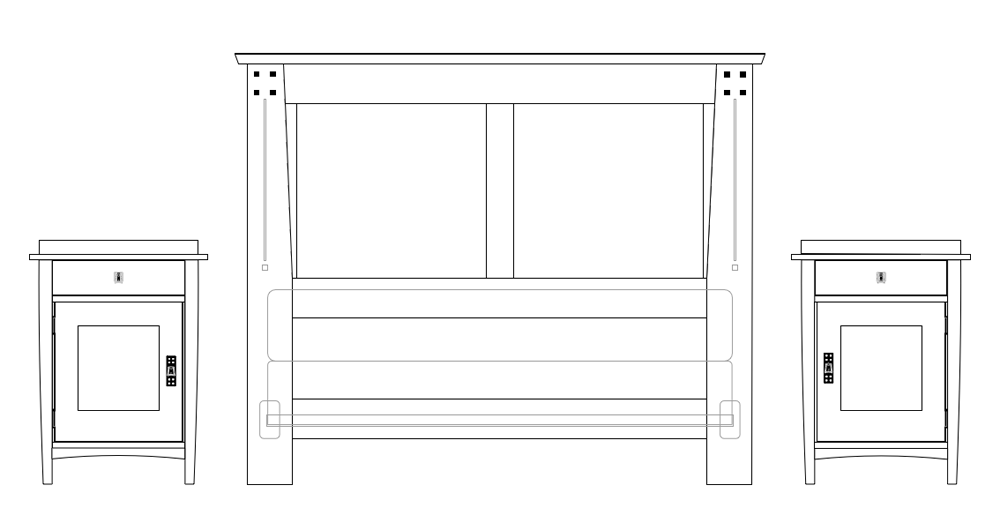

I was working on a set of bedroom furniture in the shop before the pandemic, but then we were all locked out for three months. I'm back at work, and have found a little time to restart the project. I'm building a pair of Mission style bedside tables, and a bed headboard. These pieces are pretty much right out of the Stickley catalog, with some Harvey Ellis tones thrown in. The biggest departure is in materials. Rather than the typical quarter sawn fumed oak, I'm using mahogany (sapele and sipo to be exact), which will be finished with Osmo. I need the redder tones from the mahogany for the bedroom. I'm posting just the highlights here. For a grueling blow by blow, here's a link to building thread http://www.talkfestool.com/vb/woodworking-projects/6932-mission-bedroom-furniture.html

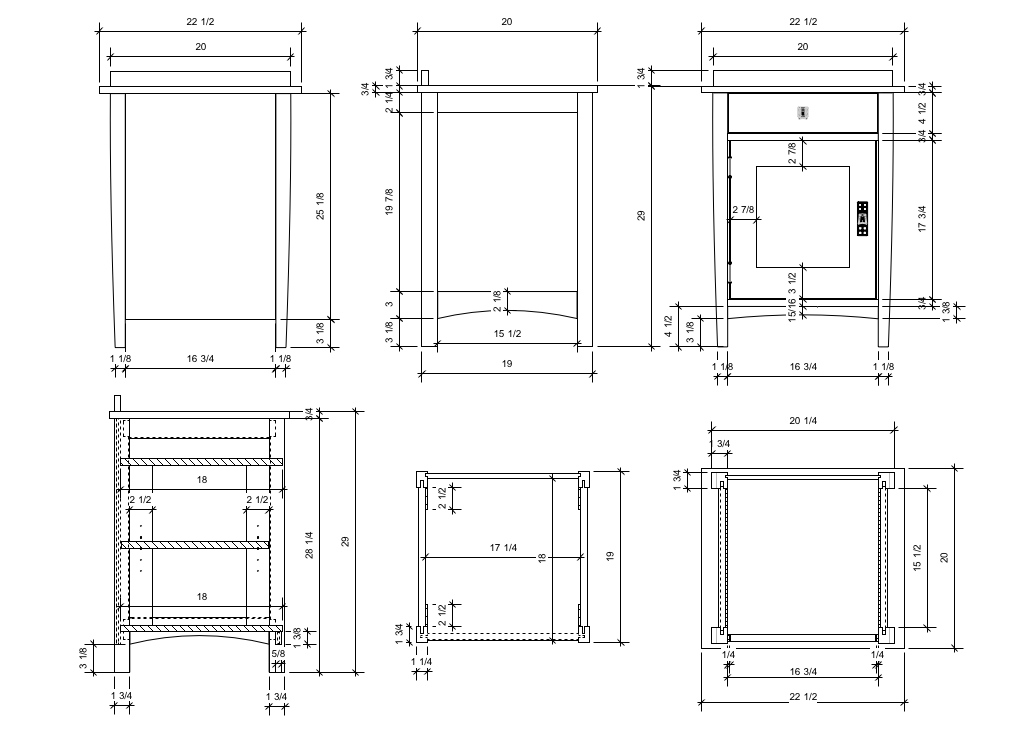

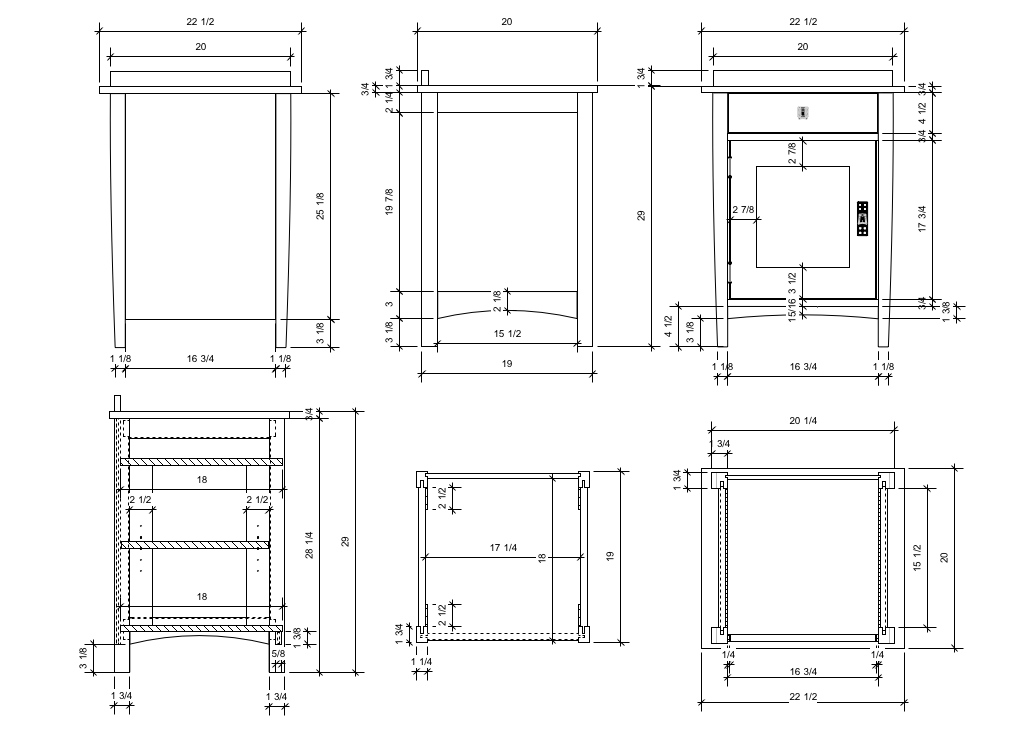

I'll start with a pic of my drawings-

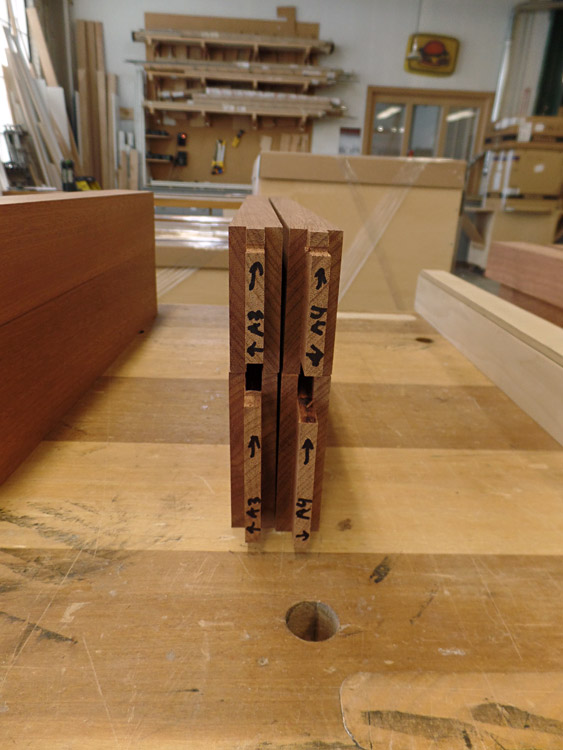

The construction is straightforward, but a little fiddly with all the notches and setbacks. The joinery is a combination of mortise and tenon, and tongue and groove. Some of the joinery is done by stationary machine, and some with my Festool Domino, with a good deal of handwork thrown in. Below is a setup piece for leg mortises.

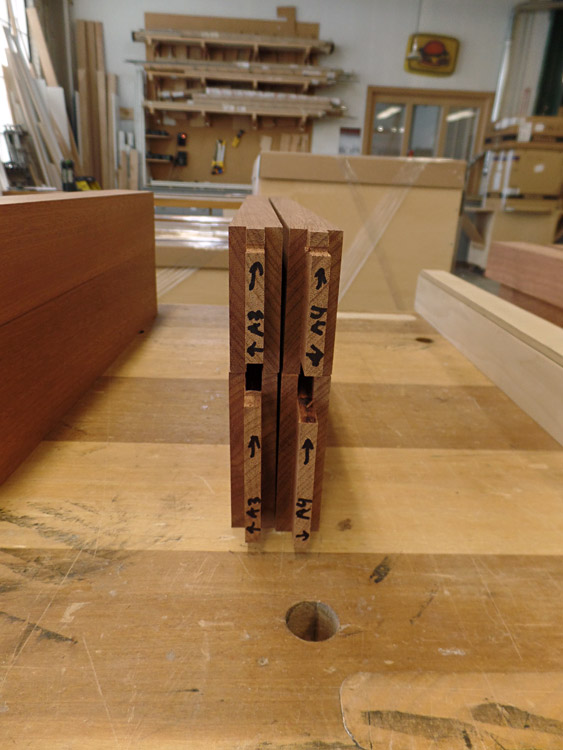

And the stack of legs. The faces of the legs have different joinery, and I had to label everything carefully to prevent mistakes (though some were made).

One side panel assembly-

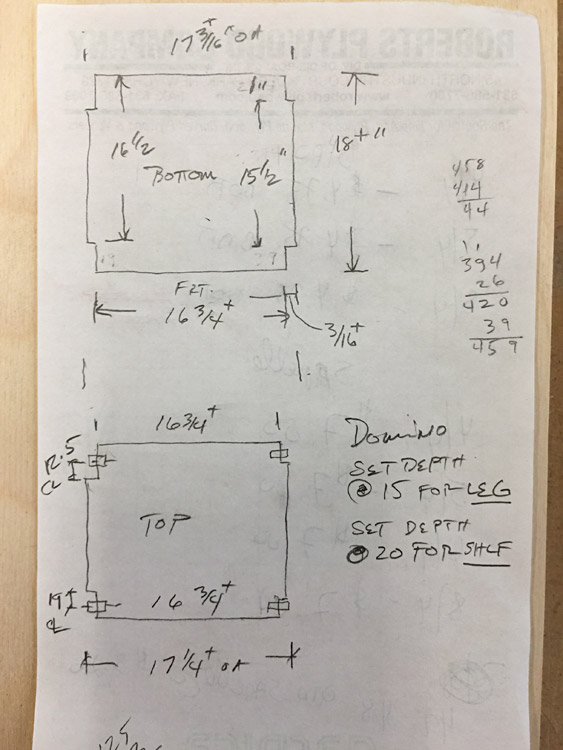

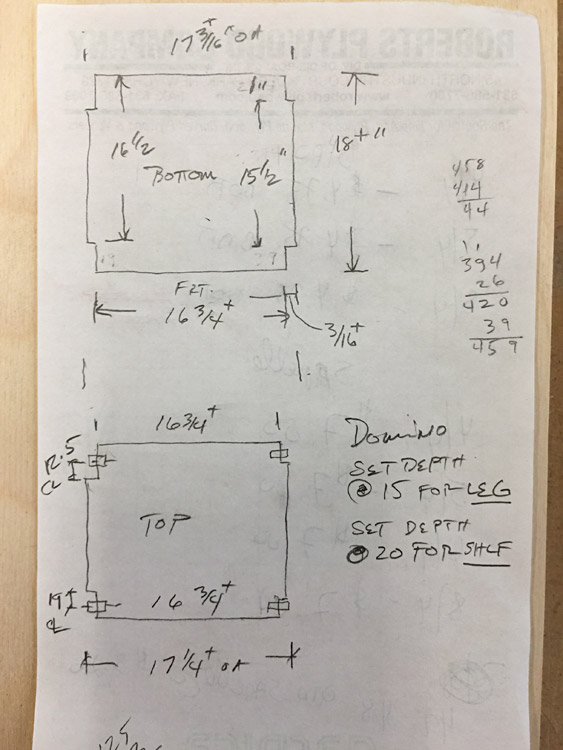

I had to carefully diagram the top and bottom shelves for notches and joinery-

I set up a dry assembly, to figure out how to clamp all of this together-

And here's the pair of tables assembled, without tops yet-

I'm working on fitting doors and drawer front today, as well as gluing up the tops. I'll bring the tables to my little home shop for finishing. More later...

Jim

I was working on a set of bedroom furniture in the shop before the pandemic, but then we were all locked out for three months. I'm back at work, and have found a little time to restart the project. I'm building a pair of Mission style bedside tables, and a bed headboard. These pieces are pretty much right out of the Stickley catalog, with some Harvey Ellis tones thrown in. The biggest departure is in materials. Rather than the typical quarter sawn fumed oak, I'm using mahogany (sapele and sipo to be exact), which will be finished with Osmo. I need the redder tones from the mahogany for the bedroom. I'm posting just the highlights here. For a grueling blow by blow, here's a link to building thread http://www.talkfestool.com/vb/woodworking-projects/6932-mission-bedroom-furniture.html

I'll start with a pic of my drawings-

The construction is straightforward, but a little fiddly with all the notches and setbacks. The joinery is a combination of mortise and tenon, and tongue and groove. Some of the joinery is done by stationary machine, and some with my Festool Domino, with a good deal of handwork thrown in. Below is a setup piece for leg mortises.

And the stack of legs. The faces of the legs have different joinery, and I had to label everything carefully to prevent mistakes (though some were made).

One side panel assembly-

I had to carefully diagram the top and bottom shelves for notches and joinery-

I set up a dry assembly, to figure out how to clamp all of this together-

And here's the pair of tables assembled, without tops yet-

I'm working on fitting doors and drawer front today, as well as gluing up the tops. I'll bring the tables to my little home shop for finishing. More later...

Jim

Capt Rich Geminski

Well-known member

Nice to see real craftmanship and real wood.

I just finished a project that has been on my "to-do" list for several years. Since the shop was built I've needed a door that separates the wood shop from the garage in my building. The summers here in Alabama have been brutal but now I've got them beat.

I went with an overhead style mostly because it doesn't use up any floor space and can be made to seal when closed. I considered several different types of doors, e.g. sliding barn door, but space constraints and air loss were key factors in the decision. Now I could have gone with a simple metal overhead door but that idea never appealed to me because I wanted the door to match the shop interior. The door is five panels with torsion box construction to stiffen it and skinned with 1/4 birch ply one one side and ship lap pine on the other side. Total weight was 500 pounds. That might seem heavy by today's standards but the guy who sold me the hardware kit said that was pretty typical for wooden doors of 40 years ago. He's been in the door business for 50 years so I took his word on the type of hardware I'd need to prevent the door from crashing down. There were a few challenges installing the door. Since there is another overhead door on the adjacent exterior wall I had to angle the tracks up-and-over the existing door. Worked out just fine doing it that way. I added another set of ceiling brackets just in case... Tensioning the springs was a bit un-nerving but went pretty well.

With the door installed I finally got an A/C in in the shop. It's a ductless mini-split and I'm thrilled with how well it cools. Alabama summers are brutal and this 3 ton so far hasn't taken very long to cool the entire shop, even when temps are in the 90s. Upper 90's inside the shop were common before the A/C. Now I can quickly cool it to 70.

I'll let the pictures do the rest of the talking.

View attachment IMG_3071.jpg

View attachment IMG_3072.jpg

View attachment IMG_3070.jpg

View attachment IMG_3075.jpg

View attachment IMG_3079.jpg

I went with an overhead style mostly because it doesn't use up any floor space and can be made to seal when closed. I considered several different types of doors, e.g. sliding barn door, but space constraints and air loss were key factors in the decision. Now I could have gone with a simple metal overhead door but that idea never appealed to me because I wanted the door to match the shop interior. The door is five panels with torsion box construction to stiffen it and skinned with 1/4 birch ply one one side and ship lap pine on the other side. Total weight was 500 pounds. That might seem heavy by today's standards but the guy who sold me the hardware kit said that was pretty typical for wooden doors of 40 years ago. He's been in the door business for 50 years so I took his word on the type of hardware I'd need to prevent the door from crashing down. There were a few challenges installing the door. Since there is another overhead door on the adjacent exterior wall I had to angle the tracks up-and-over the existing door. Worked out just fine doing it that way. I added another set of ceiling brackets just in case... Tensioning the springs was a bit un-nerving but went pretty well.

With the door installed I finally got an A/C in in the shop. It's a ductless mini-split and I'm thrilled with how well it cools. Alabama summers are brutal and this 3 ton so far hasn't taken very long to cool the entire shop, even when temps are in the 90s. Upper 90's inside the shop were common before the A/C. Now I can quickly cool it to 70.

I'll let the pictures do the rest of the talking.

View attachment IMG_3071.jpg

View attachment IMG_3072.jpg

View attachment IMG_3070.jpg

View attachment IMG_3075.jpg

View attachment IMG_3079.jpg

Last edited:

Jim

Beautiful craftsmanship. The sapele is a great choice for that style of furniture. Gustav Stickley would be proud that have come out of his shop. By the way, Craftsman period furniture and architecture is my absolute favorite.

Eric

Beautiful craftsmanship. The sapele is a great choice for that style of furniture. Gustav Stickley would be proud that have come out of his shop. By the way, Craftsman period furniture and architecture is my absolute favorite.

Eric

Steve Sanford

Well-known member

Congratulations, Eric~

Sweet door! I have considered something similar for our car barn. It has always been open (west side) without any problems year-round, but I may some make overheads for it. In keeping with the early nineteenth century architecture, I would face them with Pine - probably beaded board like the other doors on our outbuildings. I would try for a single panel - because the boards would be hung vertically. The hardware is readily available - but the springs do make me nervous....

I have a conventional AC unit in my shop. I do not use it often, but it sure makes a big difference when I need it. No 90s here yet, but high humidity 80s make work less than enjoyable for me.

Question: What unit did you use? I am thinking on something ductless for occasional use at our camp. I have been working on a small porch roof and today and building 3 clerestory windows for it - both to cool the building passively.

All the best,

SJS

Sweet door! I have considered something similar for our car barn. It has always been open (west side) without any problems year-round, but I may some make overheads for it. In keeping with the early nineteenth century architecture, I would face them with Pine - probably beaded board like the other doors on our outbuildings. I would try for a single panel - because the boards would be hung vertically. The hardware is readily available - but the springs do make me nervous....

I have a conventional AC unit in my shop. I do not use it often, but it sure makes a big difference when I need it. No 90s here yet, but high humidity 80s make work less than enjoyable for me.

Question: What unit did you use? I am thinking on something ductless for occasional use at our camp. I have been working on a small porch roof and today and building 3 clerestory windows for it - both to cool the building passively.

All the best,

SJS

Steve

My HVAC guy turned me onto to Gree mini-splits (link below). It is a 3 ton unit and cools the shop off quite quickly. It only takes a few minutes before the swamp feeling turns comfortable. I know you didn't ask but my unit was $3600 installed. Very reasonable. Especially since my employer covered $3000 for my 30 year service award. I have been waiting years for that award to cool my shop.

https://www.greecomfort.com/

Eric

My HVAC guy turned me onto to Gree mini-splits (link below). It is a 3 ton unit and cools the shop off quite quickly. It only takes a few minutes before the swamp feeling turns comfortable. I know you didn't ask but my unit was $3600 installed. Very reasonable. Especially since my employer covered $3000 for my 30 year service award. I have been waiting years for that award to cool my shop.

https://www.greecomfort.com/

Eric

Eric,

Nice club house.

Any further talk of air conditioning will force me to start a petition against such postings. I real man works in the sun or under a shade tree and wears a sweat band. You southern types complain about the cold in the winter and apparently can't take the summer heat either, sheesh. [w00t][w00t]

Nice club house.

Any further talk of air conditioning will force me to start a petition against such postings. I real man works in the sun or under a shade tree and wears a sweat band. You southern types complain about the cold in the winter and apparently can't take the summer heat either, sheesh. [w00t][w00t]

Huntindave McCann said:Eric,

Nice club house.

Any further talk of air conditioning will force me to start a petition against such postings. I real man works in the sun or under a shade tree and wears a sweat band. You southern types complain about the cold in the winter and apparently can't take the summer heat either, sheesh. [w00t][w00t]

Now Dave, If you Iowa folks had 90 days of temps in the 90s with 90% humidity you'd understand. But you pegged us on the cold weather.

Working on a duck boat, really it's been the bench for a couple months, but she is getting closer, hopefully hitting the water in August! She isn't as nice as most of the boats on here, but she is my first and I am happy with how she is coming along.View attachment 20200712_093604.jpg

Steve Sanford

Well-known member

Stephen~

You have piqued our interest! What are you building? LOA? Beam? Got more photos?

All the best,

SJS

You have piqued our interest! What are you building? LOA? Beam? Got more photos?

All the best,

SJS

I will find a few more photos, it is basically a gunning johnboat from Zack Taylor's "successful waterfowling." I modified it by lengthening it to 10'6" and extending the cockpit 6". I also adjusted some of the frames and wood dimensions for modern fiberglass and epoxy construction. I am hoping to haul it in my pickup to hit smaller potholes and marshes around the great salt lake. Right now the plan is to keep it to late and a sneakbox setup. View attachment IMG_20200629_105621_149.jpgView attachment IMG_20200629_105621_148.jpgView attachment 20200702_171730.jpg

Steve,

I am also interested in sculling, I haven't found anyone that sculls around here, but there are some locations I think would be great, so I was thinking about putting a notch in this boat and trying to learn, maybe even putting in some type of plug so I can use this as a part-time sculler. Any thoughts or recommendations would be appreciated!

I am also interested in sculling, I haven't found anyone that sculls around here, but there are some locations I think would be great, so I was thinking about putting a notch in this boat and trying to learn, maybe even putting in some type of plug so I can use this as a part-time sculler. Any thoughts or recommendations would be appreciated!

Jim Cricket

Member

Nice johnboat, Stephen! There's a fellow in Ga. that I follow on Instagram that builds some beautiful all wood johnboats. https://www.instagram.com/ogeecheeriverboatcompany/

His boats are more for fishing than gunning, but your rig has the same kind of rugged simplicity. Thought you might be interested. Keep posting!

Jim

His boats are more for fishing than gunning, but your rig has the same kind of rugged simplicity. Thought you might be interested. Keep posting!

Jim

Jim Cricket

Member

Eric, I think you're killing all of us with that work space you have. What is that, 12' ceilings? Nice work on the doors. I'll be looking forward to your cackler build, when you and your son get started.

Jim

Jim

thomas wilkins

Active member

Beautiful work Jim. Nice shop also.

Tom

Tom

Jim Cricket said:Eric, I think you're killing all of us with that work space you have. What is that, 12' ceilings? Nice work on the doors. I'll be looking forward to your cackler build, when you and your son get started.

Jim

You are correct, 12' ceilings. The Cackler build will happen. I keep thinking "next year" but when next year comes it's full of higher priority jobs. When it does happen I'll be trying to help out Stephen S's request for Devlin boat building videos by video documenting the entire build and putting it up on the duckboatsdotnet Youtube channel and Instagram. If you haven't you should check those two out. The Youtube channel hasn't had much attention, but in time it will get populated. The Instagram channel is going full bore with the help of the fine folks here.

Eric

Steve Sanford

Well-known member

Good morning, Stephen~

Very nice! Keep posting your progress - maybe in a separate post?

Taylor's book is one of my favorites - especially the boats section.

All the best,

SJS

Very nice! Keep posting your progress - maybe in a separate post?

Taylor's book is one of my favorites - especially the boats section.

All the best,

SJS